Why are suitable real-time visibility solutions more difficult to find for refrigeration logisticians?

The difficult choice of tools for temperature-controlled transports

So-called RTV platforms or real-time visibility platforms are currently a frequently-discussed topic in the market and are enjoying increasing popularity. Shippers in particular like to use these types of platforms as part of digitization projects.

As a result, carriers, transport companies, and logistics providers (3PLs, 4PLs) automatically come into contact with the platforms to provide position data to their clients, for example. In short: creating transparency during transport. Sounds simple, and in principle it is. Logically, you also want to benefit from these tools yourself.

However, when it comes to mapping sensitive transports, such as in the refrigeration and pharmaceutical industries, the whole thing looks a lot more complex. The big question here is whether classic RTV platforms are able to map the requirements of temperature-controlled transports. Because only if this is the case refrigerated logistics companies can really benefit from the tools.

My answer in a nutshell: No. Looking at the issue in a bit more detail, the following arguments, for example, come into play when choosing the right tool:

- in the case of sensitive transport flows, more is required than just creating transparency and visibility. Here, it is a matter of seamless visualization and documentation of multiple temperature sensors in multiple chambers and their setpoints, as well as information on the refrigeration machine with regard to status and error messages. As a (refrigeration) logistics specialist, you should ask yourself whether a position and the ETA alone say enough about the transport quality – for example as proof of transport – when much more comprehensive information could actually be available. Can I do without this information? Especially when things don’t go as they should?

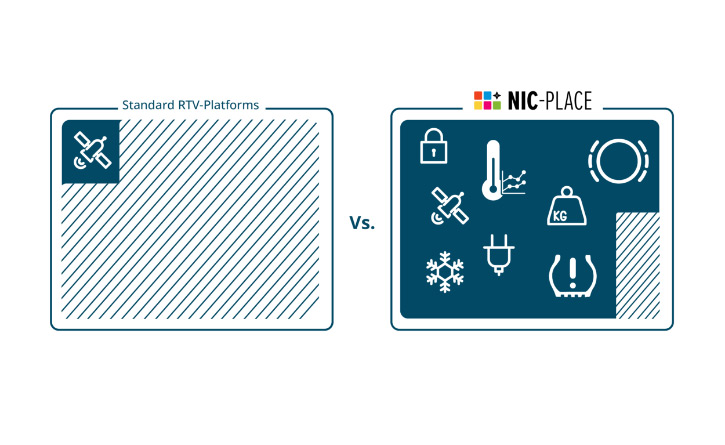

Graphic 1: Processing of all data sets with maximum data depth

Left – Standard RTV platforms: Processing of position and rudimentary temperature data.

Right – NIC-Place: processing of all data sets with maximum data depth

- In addition to temperatures, door sensors should not be forgotten. This allows loading and unloading processes to be identified automatically without driver input and provides an important safety indicator for pharmaceutical transports, for example. Sensor values for doors and locking systems therefore not only play an important role in temperature-controlled transports, but are also enormously helpful in transports with high safety relevance.

- If the platform integrates all the data required, another decision criterion becomes relevant. The system must be based on a multi-level reporting and alarm system. Otherwise, the data depth created cannot be managed in a meaningful way. “Management by exception” is the well-known catchword here!

- Of course, the requirements for an RTV platform with regard to the onboarding of the company’s own partners must not be forgotten in the selection process. Simple connection and integration of all process participants is now standard, which makes the selection somewhat easier, at least here.

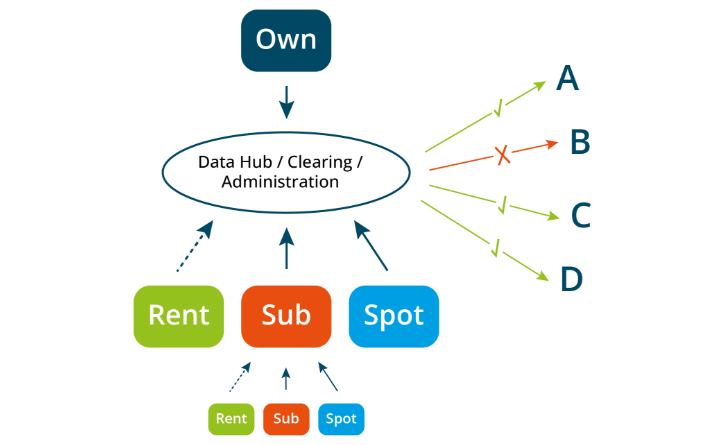

Graphic 2: Onboarding of own partner

- But what about the (refrigerated) logistics companies, which usually have more than one client and may have to serve several RTV platforms in parallel because their customers have chosen a wide variety of providers? Integrating all RTV platforms into the in-house TMS system is then a lengthy and costly undertaking, similar to integrating all partner/subcontractor telematics systems. So, the ability to easily forward data to various third-party systems becomes the next requirement in the multi-stage process of selecting the right RTV solution.

As you can see, the vendor market for collaboration solutions that meet all (five) requirements is very limited. If you also consider the very different process setups of a (refrigerated) logistics provider, it quickly becomes clear that temperature-controlled transports cannot be “squeezed” into the standards of the classic RTV platforms.

Let’s talk in person about why NIC-Place could be “the place to be” for you! For 12 years, NIC-Place has been providing software solutions for the transport and logistics industry that are holistically tailored to the transparency requirements of temperature-controlled transport. Meanwhile, the platform connects the largest cluster in Europe of refrigerated logistics providers and companies with the highest quality standards to collaborate digitally and exchange data in maximum depth.