Logistics solution automates the quality monitoring as well as the seamless documentation of Europe-wide subcontractor transports.

Food transports are strictly regulated by EU regulations in order to guarantee the quality of the products. Temperature-controlled transports are particularly critical and therefore require intensive monitoring and documentation processes. In addition, a continuously growing network of stores in almost every country in Europe requires the use of continuously new subcontractors to supply the almost 200 regional depots and ensure smooth distribution to over 10,000 retail locations. To solve these tasks successfully, a leading player in food retail in Germany and Europe relies on NIC-place.

Onboarding of the subcontractor fleet

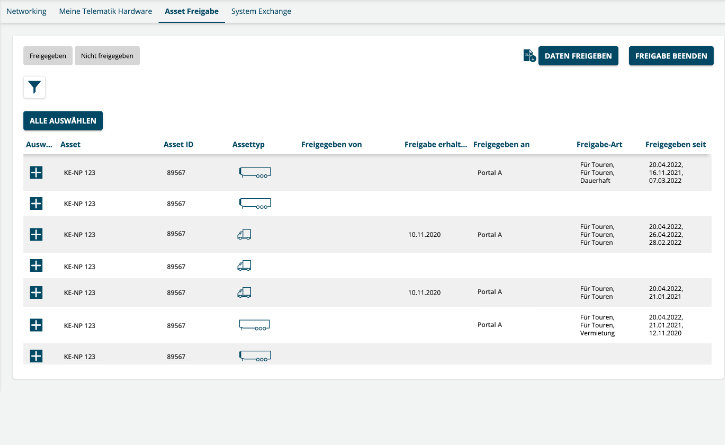

Around 5,000 subcontractor assets are used throughout Europe to transport the food portfolio of the discount retailer. So far, the assets of the more than 40 fixed transport service providers with more than 30 different telematics systems have been connected to NIC-place and prepared for data sharing in compliance with data protection regulations. In addition to already existing interfaces, the implementation of new interfaces to necessary telematics providers takes place continuously as part of the company-wide project rollout, for example with regard to the additional visualization of non-food transports. Once the subcontractor assets are activated, they provide the food retailer with relevant position and temperature data for transport, using secure data sharing processes by NIC‑place.

Graphic: Overview of the assets available for tours from the perspective of the retailer

Efficiency in daily business

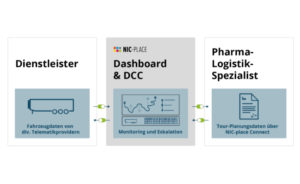

With the growing number of subcontractors, a software solution that clearly displays the 4,500 daily distribution tours across Europe in one application and at the same time reliably monitors them became essential. NIC-place enables the automated transfer of tours from the leading transport management system, ensures monitoring during the actual transport according to desired criteria and escalates deviations to desired recipients. Since the automated process was implemented, all tours are planned in the leading TMS system and live telematics data is matched to the shipments. By eliminating several telematics portals that were previously used for manual monitoring, the daily work of the dispatching staff is greatly simplified. At the same time, the automated assignment of defined monitoring criteria by NIC-place ensures monitoring in consistent quality. Individual input errors as well as forgetting settings or not activating alarm profiles can be completely avoided.

Seamless documentation

The monitoring and data transfer of subcontractor assets or transports starts and ends location-based. During transport, NIC-place monitors and escalates temperatures, reefer status, alarm codes, setpoints and GPS positions to ensure a high quality of goods at their destination. In addition, the calculation of estimated arrival times (ETA) helps to plan unloading processes at the stores as efficiently as possible. Thus, unloading only takes place if there is a continuous documentation of the transport process, including temperatures, at the store. NIC-place automatically generates a report when entering the destination POI and makes the PDF available to the defined responsible person at the ramp via email. Manual download processes or workarounds with the help of subcontractor contacts are eliminated, saving valuable time.

Graphic: Access to telematics and planning data allows automated documentation of the transport without additional effort.